Oil and gas companies are increasingly focusing on deploying new digital technologies to improve operations. Most oil and gas production facilities have been in operation for decades. To keep them running for decades, modernization through digital transformation is a necessity. The slew of new applications promises to improve asset health, sustainability, and the ability to boost production with less expense. In fact, the World Economic Forum projects that digital transformation efforts have the power to unlock around $1Tn in value for oil and gas companies.

Oil and gas companies are increasingly focusing on deploying new digital technologies to improve operations. Most oil and gas production facilities have been in operation for decades. To keep them running for decades, modernization through digital transformation is a necessity. The slew of new applications promises to improve asset health, sustainability, and the ability to boost production with less expense. In fact, the World Economic Forum projects that digital transformation efforts have the power to unlock around $1Tn in value for oil and gas companies.

However, the fossil industry hasn’t yet fully adapted advanced technologies such as artificial intelligence (AI), machine learning (ML), cloud computing, and the Internet of Things (IoT) –In fact, according to McKinsey, more than two-thirds of the world’s oil production facilities have access to advanced connectivity but aren’t using it to its full potential.[1]

What are digital twins?

Digital twins provide a virtual representative of an actual plant. They are the digital representation of the physical assets that keep the facilities operating. The Digital twins transfer every type of important information about a specific asset, such as operating instructions, schematics, troubleshooting procedures, maintenance records, and more, and store them in the cloud for easy access and updating.

Source: Asia Online Publishing Group Sdn Bhd 2022

Digital twins are used across the whole manufacturing lifecycle, from designing and planning to maintaining existing facilities. A digital twin prototype allows to monitor your equipment at all times and analyze performance data that shows how a particular part or the entirety of your plant is functioning.

How can digital twins help the oil and gas industries?

Aside from the obvious benefit of creating a single, secure repository for all asset documentation – one that doesn’t rely on the memory or expertise of an aging workforce – digital twins being the industry operational efficiency, reliability, and agility of oil and gas manufacturers.

Digital twins and smart data systems could help oil and gas operators save up to 15% on total decommissioning project cost.[4]

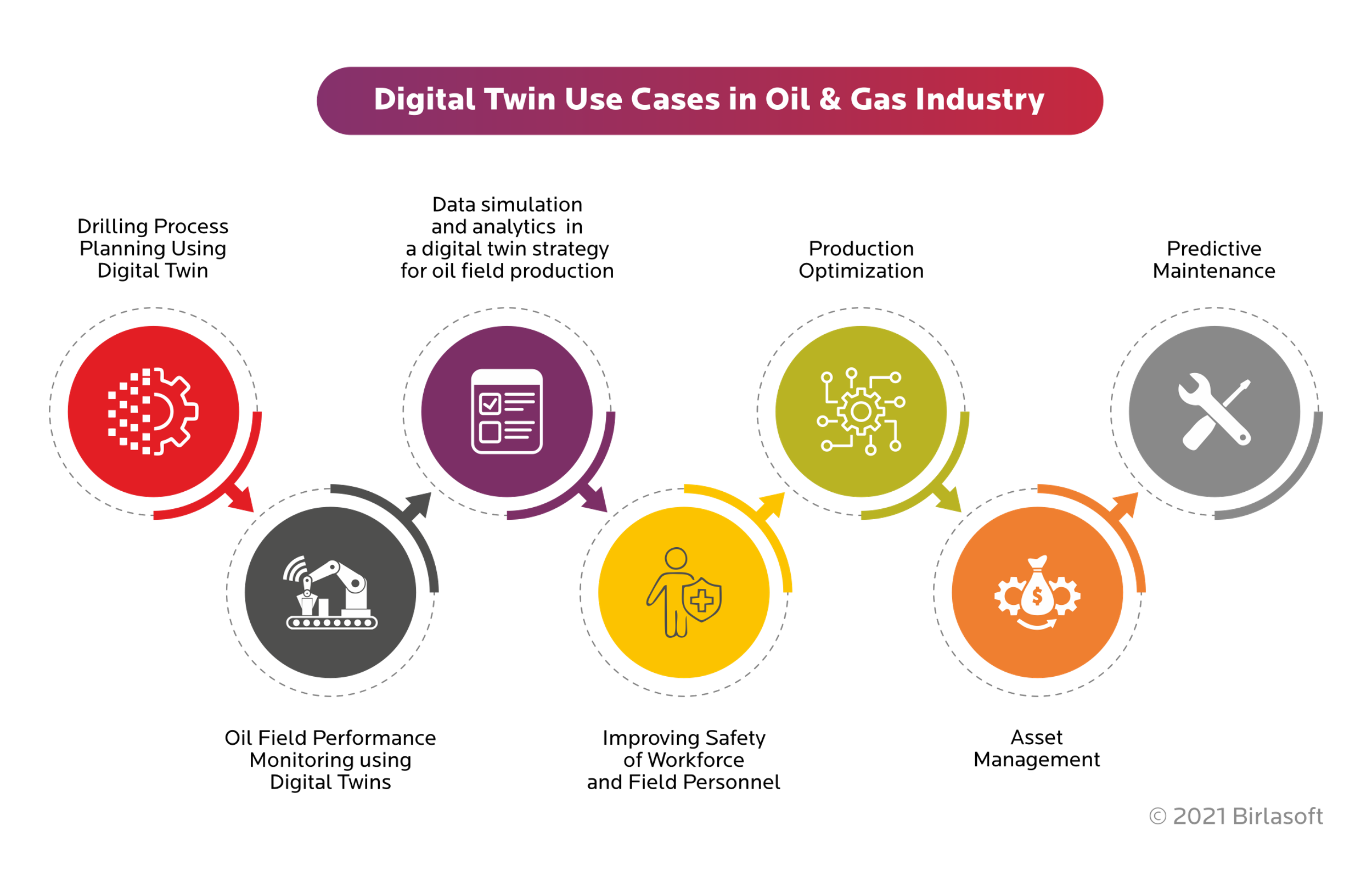

What are digital twins use cases in the Energy industry?

- Oil field monitoring and predictive maintenance

- Modeling real-life drilling scenarios to determine equipment feasibility

- Conducting dynamic simulations to arrive at optimal production workflows

- Data integration for intelligent asset management

- Increased workplace safety

Source: Birlasoft , CK Birla Group, 2021, “ What is Digital Twin Technology in the Oil & Gas Industry?” author: Lenden Vaz

- Increased yield

- Reduced unplanned downtime

- Improve workforce efficiency

- Real-time monitoring

- Improved decision-making

- Discover additional avenues for profit-making and uplift

Sources:

(1)How digital twins in the oil and gas industry can modernize your business” Ammar Sabbagh

Global Industry & Partnership manager, Erricson

(2) “How tapping connectivity in oil and gas can fuel higher performance.” McKinsey & Company. November 2020. https://www.mckinsey.com/industries/oil-and-gas/our-insights/how-tapping-connectivity-in-oil-and-gas-can-fuel-higher-performance

(3) “Oil and gas industry suffers brain drain.” Energy Digital. May 2020. https://energydigital.com/utilities/oil-and-gas-industry-suffers-brain-drain

(4)Digital Twins in 2021: 15 Amazing Examples.” UnfoldLabs. February 2021. https://unfoldlabs.medium.com/digital-twins-in-2021-15-amazing-examples-3e492d4852f5

(5)“THE INCREASING POPULARITY OF DIGITAL TWINS IN OIL AND GAS.” GEP. November 2020. https://www.gep.com/blog/mind/the-increasing-popularity-of-digital-twins-in-oil-and-gas